Building and Changing the Albacore

Employing the extremely reliable boats of the Gato, Balao and Tench classes, the U.S. submarine force scored the most complete victory of any force in any theater of war between 1939 and 1945. The submarine force destroyed 1,314 enemy ships for 5.3 million tons. The submarine force consisted of about 15,000 officers and enlisted men. This constituted less than 2 percent of the Navy, yet accounted for 55 percent of Japan's maritime losses. The submarine force suffered the loss of 52 out of 288 submarines and over 3,500 men. Included in those 52 was the first submarine Albacore (SS-218), lost in November of 1944 when she apparently struck a mine and went down with all hands.

USS Albacore (SS 218)

The Navy's first vessel named Albacore was a slow scout patrol boat loaned to the Navy in July 1917 for patrol service during World War I. She was returned to her owner in January of 1919. The keel for the second Albacore, SS-218, was laid April 21, 1941 at the Electric Boat Company of Groton, CT. Launched on February 17, 1942, she was commissioned on June 1, 1942. Albacore's war operations spanned the period between 28 August 1942 and December of 1944, during which time she completed ten war patrols.

Japanese carrier sunk by Albacore

She was credited with sinking eight Japanese ships, including an aircraft carrier, a light cruiser, and two destroyers. Her loss during her eleventh patrol on 7 November 1944 was witnessed by a Japanese patrol craft. Albacore earned the Presidential Unit Citation, nine battle stars, and other awards.

Because of their dependence on battery power, submarines were historically surface ships that occasionally dropped beneath the waves. Their basic design, including even that of the Nautilus, was predicated on this principle. Yet with the advent of nuclear power, a true submersible, which occasionally would come to the surface, was now possible. Given the right kind of hull, “a submarine no longer would have to slink along like a frightened cow at one or two knots at a depth of a few hundred feet while her tormentors rained depth charges on top of her until their supply was exhausted.” Instead, she could be the aggressor, potentially the Navy's new capital ship and the backbone of the fleet.

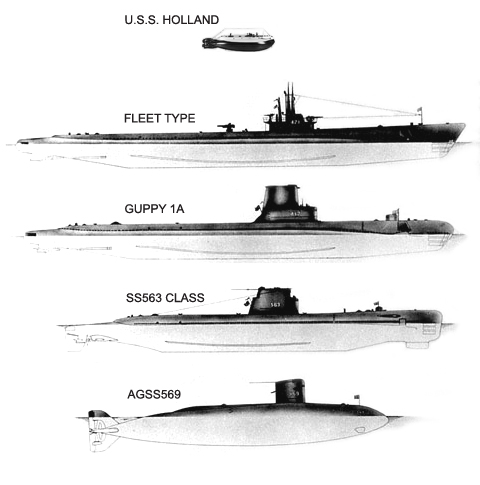

Almost immediately after the war, the submarine force began experimenting with high speed, sophisticated silencing techniques, sensitive sonic detection, and deeper diving. The result took the shape of the greater underwater propulsive power, or GUPPY, conversions which changed the shape of wartime submersibles to upgrade submerged speed and hydrodynamic efficiency. The Tang class, the first truly postwar new construction submarines, were an outgrowth of the German Type 21 submarines of WWII. The Tang class was an initial step on the road to greater submerged speed and endurance.

Evolution of Hull Shapes

Momsen- The Innovator

Following graduation from the Naval Academy in 1919, Ensign Momsen served on the battleships Oklahoma and Maryland before attending submarine training. His first submarine was USS O-13 where he was the Executive Officer. From June of 1923 through June of 1927, he had command of the submarines O-15, R-24, and S-1.

The sinking of the submarines S-51 in 1925 and S-4 in 1927, with the loss of all hands, prompted Lieutenant Momsen to begin working on a device to help trapped submariners escape safely to the surface. Momsen worked with Chief Gunner's Mate Clarence Tibbals and Frank Hobson, a civilian, to develop a device that later became known as the Momsen Lung.

The lung was an oblong rubber bag that recycled exhaled air. The air was passed through a canister of soda lime to remove carbon dioxide and oxygen was added to the cleansed air. Two tubes led to a mouthpiece: one for inhaling, the second for exhaling. The bag hung from the wearer's neck and a strap fastened it at his waist. The oxygen in the Momsen Lung allowed the submariner to slowly rise to the surface to avoid developing an embolism or the 'bends' as they were referred to. Momsen was awarded the Navy Distinguished Service Medal for testing the device at a depth of 200 feet.

During this same time, Momsen also conceived a device that could be sent down to a sunken submarine to remove multiple survivors at one time. As envisioned, this bell-shaped device would be lowered to sit over an escape hatch on the sub.

With a rubber gasket on the bottom of bell forming a watertight seal, the lower hatch on the bell and the upper escape hatch on the sub could be opened and survivors could transfer to the bell for an ascent to the surface. The cycle could be repeated until all survivors were removed.

Momsen sent his idea and drawings up the chain of command. After a year without any response, he concluded that there must have been a technical problem with his concept. He later found that it was disapproved as being impractical.

Not to be discouraged, Momsen built a prototype bell and tested it off Key West, Florida. He reported the bell was unstable, tipped, and leaked, but before he could institute any changes, he was sent off to teach submariners how to use the Momsen Lung. Lieutenant Commander Al McCann was put in charge of making revisions to the diving bell that, in late 1930, was named the McCann Submarine Rescue Chamber. Momsen used this chamber to rescue the 33 surviving crew members of the USS Squalus that sank off the coast of New Hampshire in May of 1939.

From 1937 to 1939, Momsen led the experimental deep-sea diving unit at the Washington Navy Yard. It was during this time that the diving team experimented with and developed tables of helium and oxygen mixtures that permitted divers to safely operate at depths greater than 300 feet. By substituting helium for the nitrogen in the air mixture, divers were not subjected to the feeling of euphoria called "nitrogen narcosis."

During World War II, Momsen served as Command Submarine Squadron (ComSubRon) 2 and 4. While serving as ComSubRon 2, his submarine captains reported that their torpedoes were not always detonating when striking their targets at a perpendicular angle. Momsen took torpedoes and fired them at an underwater cliff until he got a dud. Momsen dove into the water and, with help, recovered the unexploded torpedo. Analysis of the firing mechanism revealed that the firing pin was being crushed on impact before it could reach the primer cap of the warhead. As a result, the firing pin was made stronger and the number of duds was reduced.

Soon after WWII, the Committee on Undersea Warfare (CUW), a subset of the National Academy of Sciences, proposed that a submarine be designed for maximum submerged performance. In July of 1948, the Chief of Naval Research requested that CUW investigate the hydrodynamics of submerged bodies. In November of 1949, the committee submitted its "Interim Report of the Committee on Undersea Warfare Panel on the Hydrodynamics of Submerged Bodies" which contained a strong suggestion that the Navy design and build a high-speed research submarine capable of exceeding 20 knots submerged. A copy of this report arrived on Admiral Momsen's desk in January of 1950, when he was the Assistant Chief of Naval Operations for Undersea Warfare. Momsen was very instrumental in the design and operational capabilities of our modern submarine.

Momsen - The Advocate of the Modern Submarine

Under the leadership of Admiral Charles "Swede" Momsen, Albacore was conceived to inaugurate a radical change in submarine design. World War II experience had shown that speed, endurance, and maneuverability were key requirements for submarines. Albacore's hull was to be designed with underwater speed as the prime requirement.

Captain Hyman Rickover took a different approach toward creating a true submersible. The power source, not the hull, was the key to his vision. The Nautilus was the result of joining Rickover's nuclear power plant with the Tang class submarine hull.

USS Nautilus (SSN 571)

To speak openly of what Momsen privately envisioned would invite a fast trip to the booby hatch. Guile was the key to circumvent establishment thinking. In a carrier-dominated Navy, he knew there was no chance that funds would be appropriated for such a radical purpose. But he also knew that carrier admirals feared submarines. And that was the leverage he used. He submitted his proposal as a target for submarine hunter-killer groups to practice on. Approval was immediate.

Since, as a target, she would not be armed, Momsen made sure that only the Bureau of Ships would be involved in her creation. The designers did not have to concern themselves with any input from the Bureaus of Ordnance, Engineering, Navigation, and Construction and Repair which, as Momsen remarked, always ended up stuffing a submarine like a "turkey." His instructions to the designers were to the point: "Forget about surface performance. Think only about submerged capability which will provide the utmost speed with minimum of power. When in doubt, think speed."

Dirigible - One of the shapes evaluated as part of Albacore’s hull design process

An investigation was made into every conceivable shape, including aircraft and blimps, for clues to the hydrodynamic performance Momsen sought. Endless tests were conducted. More than twenty-five scale models were produced, ranging in size from seven to twenty-five feet in length. Blunt-nosed and wide-bodied amidships, the final version was shaped like a fish with a cod's head and a mackerel's tail.

Albacore Model in Wind Tunnel

Topside, she had only a rakish, slender tower, called a sail, that housed the necessary masts and antennae. Attached to the rear end of the sail was a controllable dorsal-like rudder. Since the twin screws on conventional subs were primarily for surface maneuvering and actually impeded their thrust underwater, she had only one five-bladed propeller.

Admiral Momsen at Albacore’s commissioning

Named Albacore, she was commissioned on December 5, 1953. Addressing her officers and crew, Momsen told them that the future was in their hands, that “this boat upon which so much depends may lead the way to mastery of the sea by submersible.” Her official motto, "Praenuntius Futuri" or "Forerunner of the Future" was to prove appropriately chosen for the many innovative systems and devices that were to be tried on Albacore.

Even with her limited conventional battery power, she could reach twenty-seven knots in short bursts. But speed was not her sole asset. She could do tight turns and dives as if she were a jet plane. In fact, her control room resembled the cockpit of a jet, her diving officer directing her course and depth with a single "stick" while strapped into a bucket seat complete with seat belt. Her crew, as she dived and turned with startling swiftness, hung on to overhead straps like subway riders.

One man control - the Pilot

To Swede Momsen's delight, Albacore was a bust as a target. She easily outran and outmaneuvered anything that went after her. It would take time, but the end was inevitable. From Albacore, the design all of the Navy's modern, nuclear-powered submarines has evolved.

Post-Albacore Skipjack and Thresher class models

Just as the battleship once fought a losing battle for primacy against the aircraft carrier, so the nuclear power of the Nautilus married to the Albacore's hull configuration became the centerpiece of the fleet.

Placed in commission in December of 1953, Albacore was to serve until September of 1972 when she was decommissioned and moved to the Inactive Ship Facility at Philadelphia. She remained in Philadelphia until 1984 when she was towed to Portsmouth and later moved in 1985 to her current location in Albacore Park.

Albacore in the park

In 1989, Albacore was designated a National Historic Landmark due to her contributions to submarine design. In 2000, she was further honored with the designation of being a Historic Mechanical Engineering Landmark for her many unique systems and a Historic Welded Structure for her hull. In May of 2005, Albacore was inducted into the Submarine Hall of Fame in Norfolk, Virginia for her contributions to submarine engineering and tactics.

The Test Phases

Progression of control surface/propulsion configurations

During her period of service, Albacore went through a number of pre-planned major conversions that were intended to examine various aspects of submerged control. As originally built (Phase 1), there were small bow planes forward, a “dorsal” rudder on the after end of the sail, and a rudder and diving planes located behind a single large 11-foot diameter, five-bladed propeller.

Dorsal rudder

Phase 1 Albacore on the building ways

This arrangement provided excellent slow speed submerged maneuverability but placed high stress on the control surfaces and their supporting structures. It was during Phase 1 trials that Albacore first set the underwater speed record. Also during this phase, Albacore had her propeller removed and was towed submerged to obtain data for comparison of ship characteristics with and without a propeller. This was another first for Albacore.

The second (Phase 2) configuration removed the dorsal rudder and moved the after control surfaces forward of the propeller. This arrangement provided excellent high speed maneuverability and was less stressful on the supporting structures. As part of noise reduction trials, the bow planes were removed during this phase.

Bow planes to be removed during Phase 2

Trials with a new design, fourteen foot diameter propeller were undertaken. A series of tests were also run to evaluate a concave bow sonar dome.

Phase 3 control surfaces

A third modification (Phase 3) placed the after control surfaces in an X-configuration which increased the size of the controls for greater maneuverability and reintroduced the dorsal rudder. A new bow was installed and a series of ten dive brakes were installed around the periphery of the hull.

The next (Phase 4) configuration added a second main motor driving a second, counter-rotating propeller for greater propulsion efficiency. A high capacity silver-zinc battery was installed as was a new, semi-automatic propulsion control cubicle. Also installed were an emergency recovery system and a new main ballast tank blow system.

A final, fifth phase introduced a boundary-layer control system for reducing water friction and turbulence. The approaching exhaustion of engine repair parts curtailed operations and eventually led to Albacore's decommissioning in 1972.

The Devices/Systems Investigated

One of the principal areas of concern with high underwater speed that Albacore was designed to investigate was that of control of the submarine. A jammed set of controls could drive the boat below its crush depth in seconds. Testing revealed that putting on full rudder would cause to stern to squat and at the same time the increased drag of the control surfaces would slow the ship. High speed turns also produced a sharp, sudden (snap) roll in the direction of the turn. To counter that snap roll, an extra “dorsal” rudder was placed on the after end of the sail. Again through trials, it was determined that adequate control could be maintained without using the dorsal rudder.

The hydraulic system that moved the planes, raised and lowered the periscope and masts was of an improved design that added safety and flexibility. The 3000 psi system, operating at a higher pressure, was first installed on the Tang class submarines where it had many problems. By the time Albacore's system was installed, the bugs had been worked out.

Hydraulic station -- life blood of control systems

The large rudder and stern planes of Phase 1 offered too much control surfaces at higher speeds. To lessen the opportunity to over-control, small aircraft type trim tabs were installed near the large control surfaces. With proper adjustment, these small controls minimized the use of the large controls.

Single stick control station

Albacore pioneered the single control yoke for bow and stern planes and rudder. Thus, one person (the pilot) was able to perform the functions formerly done by three. By combining other functions, the number of crew members required to dive and operate the boat submerged was reduced from ten to three - the Conning Officer, a pilot, and another crew member to operate the blow and vent and trim manifolds.

Another Albacore first was the use of a single, multipurpose mast housing a number of antennas. She also carried a single experimental periscope that combined the functions of the thin attack scope and the large aperture search scope.

Albacore's single periscope

Albacore evaluated ship handling procedures for a single screw submarine in confined waters and evaluated tactics for high speed, maneuverable submarines of the future.

Combined Instrumentation Panel

A Combined Instrumentation Panel placed a set of miniaturized instruments in front of the pilot and co-pilot. These instruments included a depth gauge, inclination bubble, gyro repeater, and bow and stern plane indicators. An aircraft artificial horizon was used as a single flight instrument for high speed submerged cruising.

An autopilot system was also tried on Albacore. It was essentially a system borrowed from a blimp. The system eliminated human failures due to lack of coordination or slow reaction, stress, fatigue, boredom, and distraction. With the autopilot engaged, the boat was quieter and operated with less large control surface motion.

The installed pancake diesel engines were a constant aggravation. They were a radical departure from the proven diesels used in earlier boats in that they were made of aluminum and ran at twice the speed of the earlier engines. They were under-powered to charge the ship's batteries and had a severe tendency to breakdown. But they were the only engines available that would fit into the cramped space set aside for Albacore's engine rooms. It was cannibalization of the 16 cast-off engines taken from the Tang class of submarines that kept Albacore's engines going for 19 years. When those parts were exhausted, Albacore's life was over.

Phase 2 modifications included moving the stern planes and rudder forward of the propeller. Low speed maneuverability was degraded to some extent but high speed stability was improved. Taking the planes out of the prop wash reduced noise.

The bow planes were removed after Phase 1 testing showed that they were noisy and more of a hindrance than a help in depth control. The dorsal rudder also was removed in Phase 2.

The eleven foot diameter propeller was replaced with a new design, fourteen foot propeller.

With the Phase 3 addition of the x-stern bringing back concern for the snap roll, the dorsal rudder was reintroduced to counter the expected snap roll and a series of ten dive brakes around the circumference of the hull were added to aid in slowing the boat down in case of an uncontrolled high speed dive. Although the dive brakes performed as intended, they had a tendency to open on their own at high speeds due to the action of the water flowing over their surfaces.

Dive Brakes

An earlier alternate to the dive brakes was the use of a large parachute, borrowed from the local Air Force base, which was used to decelerate a B-47 jet bomber after landing. The chute was mounted on the top of the sail with the expectation that the deployed chute would not only slow the boat down but would also pull the bow up and decrease the down angle. The chute ripped off on its third or fourth try and was deemed impractical.

To minimize the amount of noise being radiated into the water and thus decrease a submarine's detectability by hostile forces, Albacore's noise producing machinery was placed on sound-isolation mountings.

Albacore introduced the fiber-glass sonar dome which is standard equipment on all current submarines. A bread-board version of the DIMUS (Digital Multibeam Steering) sonar was tried on Albacore. DIMUS was to be the basis of all our sonars.

She was also the first submarine to use a towed array. Originally intended to measure near-field noise generated by the submarine, the towed array evolved into a sonar system today used to detect other submarines.

Stern removed for new aft section

As part of the Phase 4 conversion, the hull was cut at the engine rooms and a new aft section installed. This section included a second main motor which drove a second, contra-rotating propeller aft of the original propeller. The single propeller was replaced by a 10-foot diameter, seven-bladed forward propeller and an 8-foot diameter, six-bladed after propeller. Spacing between the two propellers was originally set at 10-feet. A video camera system was installed that allowed the engineers to see in real time the water flow through the propellers and the formation of noise producing cavitation bubbles. After trials at the 10-foot interval were completed, the decision was made to skip the 7.5-foot spacing and go to the 5-foot spacing. The engineers were seeking the optimum spacing interval for propulsion efficiency which, as predicted, turned out to be 5 feet. The nuclear powered submarine USS Jack (SSN 605) was the only other US submarine to be equipped with contra-rotating propellers.

Concurrent with the installation of contra-rotating propellers, Albacore received a high capacity silver-zinc battery with many times the energy storage capacity of the lead-acid battery it replaced. It was with this battery that Albacore reclaimed the title of the world's fastest submarine in 1966.

A new combined radio antenna system and associated radio equipment were installed as part of Phase 3. The original equipment consisted of leftovers and had been characterized as the “worst in the Navy” by one commanding officer who, at the end of a transit through the Cape Cod Canal, gave the pilot a dollar and asked him to phone the base and report that they were alright.

A “vernier” system of rudder and stern plane control was also installed as part of Phase 4. Above a set speed, usually 20 knots, this system was activated which caused the control surfaces to receive reduced signals from the control wheels. The resulting smaller control surface movements reduced the possibility of over-control at high speeds.

A totally separate hydraulic system was added during Phase 4 that gave the Conning Officer the capability to take control of the stern planes in case of a casualty. Operation of the system was by a lever, referred to as the “chicken switch,” which was located overhead at the conning station in the Control Room.

The loss of the Thresher brought about a review of existing ballast tank blow systems which determined that valve and piping changes were necessary to maximize air flow to the tanks. Albacore tested various components of an improved ballast tank blow system which was incorporated in all submarines.

Surface test of ballast tank blow system

New construction submarines and those coming out of overhaul had to go through a set of sound trials to determine the noise radiated into the ocean by the boat from its machinery and hull. These trials usually took place at a special test range far away from the shipyard and the boat's home port. In an effort to perform these tests nearer to a subs home port, the Fly Around Body (FAB) was developed. Essentially a small, controllable, winged body towed off the bow of the submarine, the FAB “flew” a hydrophone array around the body of the submarine. Radiated noise was recorded as machinery was turned on and off. Difficulties in deploying the FAB system under less than ideal sea conditions (sea state 2 or less) rendered the system impractical.

FAB nose cone adapter

A final Phase 5 was established to test a method for reducing the friction of the water flowing over the hull and thereby increasing the ship's speed. Dubbed the “Slippery Water” project by the crew, it involved the release of a viscous polymer liquid that would coat the hull and reduce drag. Early trials showed that the system produced positive results. However, engine breakdowns hampered the ability of Albacore to complete the trial series and so the project was ultimately canceled.

Life on Board

Going to sea on a submarine can not be compared to any other type of sea-going vessel. There are no decks you can walk on for a breath of fresh air and the tiny bridge could only hold two people at a time. The interior has a bewildering array of equipment jammed into every conceivable corner. Space for people comforts are few.

Crew’s berthing

On Albacore, due to her research mission, these comforts were even less than those on other boats. While there were just enough bunks for the assigned crew, there were always additional "riders" or test personnel on board when trials or tests were conducted. Test instrumentation was usually set up in the bow compartment taking over several bunks thereby forcing their occupants to “hot bunk” with other crew members. The Officers Wardroom in the Forward Battery compartment was their dining room, work/study area and, on occasions, auxiliary bunk room (the outboard settee could be converted into two bunks). The only space where the enlisted men could spread out and relax was the Crew’s Mess.

Crew’s mess

Located in the After Battery compartment, the three six-man tables in this area served as their dining room, study hall, movie theater, and lecture hall. Although accommodations were basic at best, no one was on board who didn't want to be there. And there were moments of fun and high anxiety. Some examples follow.

In dry dock

Albacore spent a lot of time in dry dock. In dock, Albacore's deck was 35 to 40 feet above the concrete dock floor. The rounded hull and small walking surface of her deck were cause for concern for her topside watch standers. Yard workers erected wooden railings around the deck with safety netting and kick boards to prevent people and objects from falling off the boat. However, nothing is foolproof. Electronics Technician Jim Tyrell: "We were in dock and I had the 4 to 8 watch. Just before I was to be relieved, I toured the boat and somehow fell through the protective wooden railing. I hit some scaffolding on the way down and landed in the bottom of the dock. Tony Szymbor saw me fall and rushed to the bottom of the dock where I laid stunned. After a short while, I was able to get to my feet with Tony's help and climb out of the dock in time to be relieved. To this day, I don't think anyone but Tony believes that I fell into the dock and was able to walk away."

The round shape of Albacore's hull made for uncomfortable riding on the surface in any kind of a sea. The natural tendency was for the boat to submerge when running into any kind of a sea. A vivid example was Albacore's encounter with a hurricane when returning to Portsmouth from Florida after a trial period off Ft. Lauderdale.

Rough passage during hurricane (pictured above and below)

Yeoman Butch Jordan: "I can remember we ran into a hurricane on our way home from Florida. Heavy waves were pounding us and coming over the top of the sail. We had to secure the bridge watch and send the OOD and lookout down to the Control Room. Water was coming into the boat through the main air induction and filling the machinery space bilges. We had to keep the main induction open to run the engines because our battery was pretty flat. Fortunately, we ran out of the storm before we flooded the bilges or ran out of battery. The control room watch observed the digital depth gauge cycling between 9 and 60 feet - while running on the surface!"

As stated previously, Albacore's large control surfaces and streamlined hull shape made the boat very responsive to steering and diving commands. Electronics Technician Jim Tyrell: "I actually learned to fly on the Albacore. A few years after I got out of the Navy, I took flying lessons. The instructor was amazed I could fly a plane the first time I tried. It felt exactly like flying the Albacore."

Not all our time was spent at sea. Albacore was a frequent visitor to Florida where the weather was usually cooperative for running trials. Radioman David Grossnickle: "I reported aboard along with Chief "Pappy" Powers, a World War II submarine veteran. We were in Ft. Lauderdale doing daily operations. It was late in the evening and some of us were topside enjoying the evening air when this convertible pulls up to the boat. Two NROTC midshipmen get out and walk over to Pappy and order him to get their bags out of the car and stow them below. There was a moment of stunned silence. Then Pappy walked over to the car, got their bags and started over the brow. About half way over, the bags 'slipped' out of Pappy's hands and fell into the water. Then Pappy turned and, in the way only a salty old chief can talk, explained to these two young men how the Navy operated. It was a memorable scene."

Not everything was done by the book. Electronics Technician Jim Tyrell: "We sometimes thought up funny things to break up the monotony when underway. One thing we did was to form human trim parties. We had a new officer learning how to trim the boat and six of us would walk from the bow compartment aft to the machinery space which would throw his trim off. By moving aft, the six of us were making the bow of the boat about 1000 pounds light and the aft end 1000 pounds heavy. We would wait awhile until he got the trim perfect before walking forward to the bow compartment. Pretty soon the trim pump would start up to adjust the trim. We would head aft again to mess up the trim. Finally the Chief of the Watch told on us and we were ordered to stay in one place."

In spite of the most careful planning, testing didn't always go according to plans. Quartermaster Norm Bower: "I remember when we were going for the submerged speed record the first time. We had just gone to maximum power when the main battery circuit breaker in the forward battery tripped with a load bang. Suddenly, all the lights went out. There was a period of about eight seconds when we it was pitch black and we couldn't see our instruments. Imagine driving down the highway at 30 miles per hour with your eyes closed for 8 seconds. Finally the emergency lighting came on and we could see our gages again."

Weight and balance are critical to submarine operations. Before each dive, a careful calculation is made to adjust the trim tanks to account for things like equipment removed/added/relocated, stores taken aboard, and fuel and water tanks being topped off. Most of the time this calculation produces a 'compensation' that pretty accurately balances the boat and allows it to submerge with only minor adjustments. However, this isn't always the case.

Sonar Consoles

Sonarman Ashley Fletcher: "I remember the time we were coming out of the yard and on our first dive, the bow dropped like a rock. I was in Sonar watching the SONAR screen in front of me while sitting in my chair. Next thing I knew, the screen was up on the ceiling and we were headed straight down and wound up bouncing off the bottom several times. Fortunately, we were only in about 300 feet of water. Everything was dark and quiet until the Captain gave the order to switch to emergency lighting and ‘Blow the forward tanks, all back full.’ We wound up surfacing backwards."

The food in the submarine force is the best in the Navy. Considering the small space allotted to the galley, the food that comes out of there is amazing. The cooks prepared breakfast, lunch and dinner for the crew of 55 plus any visitors/trial personnel. In addition, a mid afternoon meal known as "soup down," consisting of hot soup and sandwiches was served as were "mid rats" or midnight rations at 2315 at night. From this same small galley, the ship's baker made fresh rolls, bread, pies, cakes, sticky buns and other pastries. When in port at Portsmouth on Friday at noon, the crew had a special meal. Commissaryman Henry "Shakey" Graves: "Albacore was a great feeder even by submarine standards. Every other Friday noon we served either fresh boiled lobster or lobster newburgh. On newburgh Friday's, I would go to the Executive Officer and ask him to take the secret newburgh ingredient - a bottle of sherry - out of his safe. Because the Navy was dry, we were not supposed to have anything but medicinal alcohol on board. The Captains were told when they took command not to ask what was in the newburgh that made it taste so good. You could say this was an early instance of ‘don't ask, don't tell’ in the Navy."

Periodically, every submarine is required to make a dive down to its maximum operating depth, known as "test depth," to make sure that the hull remains watertight and that all systems can still function under conditions of maximum water pressure. As with most tests, extra precautions are taken and extra personnel are on watch throughout the boat. Lt. Jack Hunter: "I was in Maneuvering during one of our deep dives when I heard a crackling sound and saw smoke coming out of the propulsion cubicle. Electrician Tony Szymbor secured the power to the main motors and announced "Fire in the cubicle." With the removal of power, the smoke stopped, so Tony announced "Fire is out." When Tony tried to restore power to the propulsion motors, nothing happened. He then notified Control that he was unable to answer any bells. Whatever had burned inside the cubicle had disabled the main motors. So there we were at test depth and slowing down with no way to drive ourselves to the surface. It was a couple of heartbeats later when I felt and heard the emergency blow system activated and we started up to the surface."

As mentioned earlier, Albacore tested an improved ballast tank blow system. Not being sure how the boat would respond to this new system, a deliberate series of tests were planned. Quartermaster Norm Bower: "After the Thresher was lost, the Navy developed a more effective system for blowing ballast tanks. We were the first to try out this improved system. After testing the system on the surface, we went to sea to test it submerged.

Successful emergency ballast tank blow system test

Our first test was from a depth of 100 feet from a dead stop. The blow was initiated and the boat rose rapidly to the surface. The second test was to be from 500 feet, but the Captain decided to do one from 300 feet instead. When the blow began, the boat immediately took a huge (reportedly 54 degree) angle to starboard and stayed that way until we reached the surface. The engineers later told us that because we had no way or forward motion on, our sail acted like an extra control surface and caused the boat to take that huge angle. We had way on when we did the blow from 500 feet and we shot to the surface with no problem."